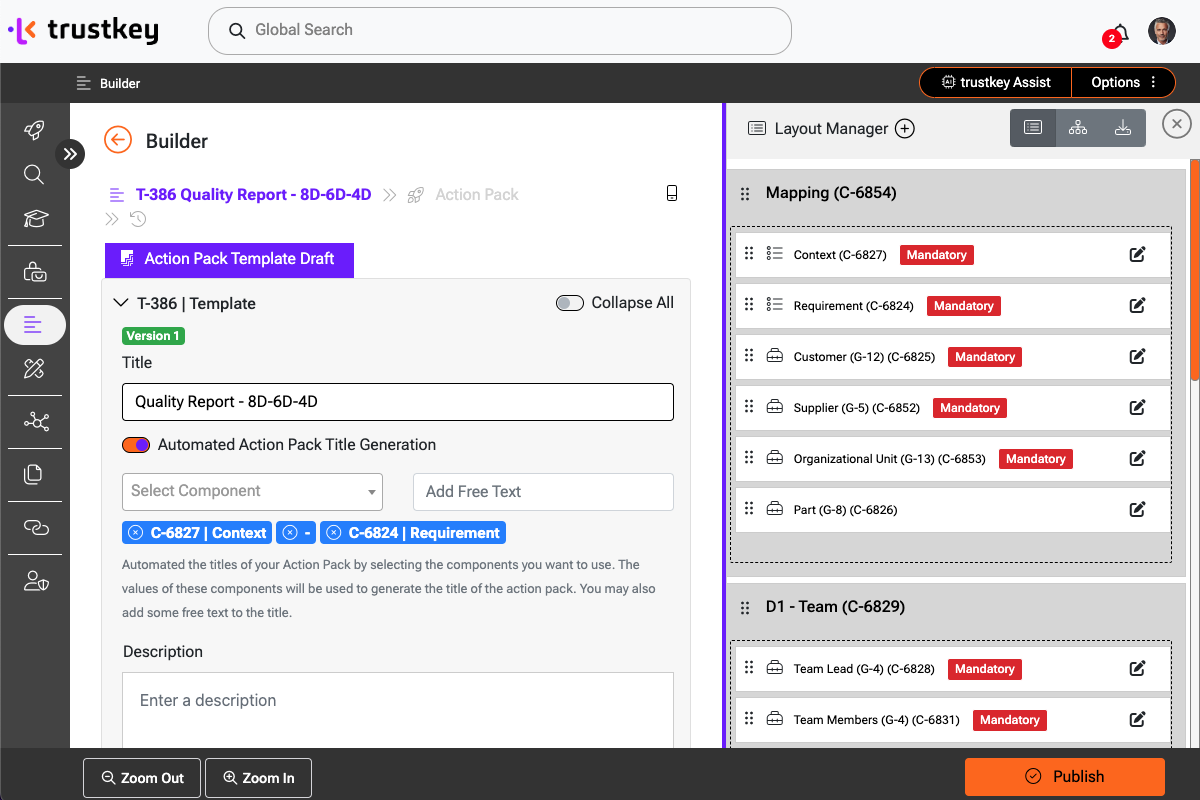

Use Case: A Manufacturing Company

A manufacturing company often encounters quality issues with one of its components. To systematically address the problem, the company employs the 8D process. By integrating a PES, the company automates data collection and analysis for the 8D report, monitors progress in real-time, and enhances team communication. Consequently, this leads to faster and more accurate problem-solving, resulting in long-term improvements and cost savings:

Time to Resolve (TTR): From 30 to 14 Days

Before:

Previously, the average time to resolve a problem was 30 days, causing long production downtimes and high inventories of defective components.

After:

By automating data collection and analysis, as well as enhancing team communication and collaboration, the time to resolve issues was more than halved to 14 days.

Repeat Issue Rate (RIR): From 20% to 4%

Before:

Earlier, the repeat issue rate was 20%, meaning every fifth problem reoccurred shortly after being resolved.

After:

Through precise root cause analysis and the implementation of permanent corrective actions, the repeat issue rate was reduced to 4%.

Cost of Problem Resolution (CPR): From €40,000 to €16,500

Before:

Previously, the cost of problem resolution averaged €40,000 per issue, including labor costs, material costs, and production downtime costs.

After:

By efficiently utilizing PES and optimizing the problem-solving processes, the cost of problem resolution was reduced to an average of €16,500 per issue.